NEWS

Matters needing attention in stainless steel processing and construction

Release time:

2021-02-17

By: GKVAC

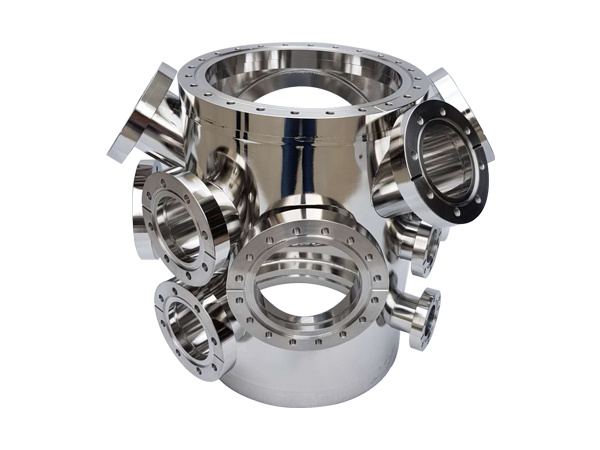

Stainless steel production and processing Because the compression strength of stainless steel is higher than that of common raw materials, the stamping die and its cutting must have higher working pressure, and the cutter and cutter clearance cannot produce cutting. Choose low temperature plasma or laser disconnection to prevent poor change and cold work hardening. When oxygen cutting or electrical insulation is forced, hot hazard areas should be milled and heat treatment must be performed. Let's take a look at the matters needing attention in stainless steel processing and construction.

Stainless steel production and processing Because the compression strength of stainless steel is higher than that of common raw materials, the stamping die and its cutting must have higher working pressure, and the cutter and cutter clearance cannot produce cutting. Choose low temperature plasma or laser disconnection to prevent poor change and cold work hardening. When oxygen cutting or electrical insulation is forced, hot hazard areas should be milled and heat treatment must be performed. Let's take a look at the matters needing attention in stainless steel processing and construction.

1. Sheet metal bending production and processing. Thin plates can be bent to 180 degrees, but in order to better reduce cracks on the curved surface, the radius along the injection direction is twice the thickness of the plate, while thick steel plates are twice the thickness of the plate and bent vertically. When stainless steel is processed and folded, especially during welding, the thickness of the plate must be warped by half to four times the thickness of the plate, so as to better avoid production and processing cracks and solve the welding area for surface grinding.

2. Stainless steel processing is easy to produce friction heat during production and processing, so stainless steel with high pressure resistance and high temperature resistance should be used. In addition, after production and processing, oil attached to the surface should be removed.

3. Before stainless steel processing and welding, rust, oil stain, moisture, paint, etc., which are harmful to welding, should be thoroughly removed, and welding wires of appropriate steel grades should be selected. The welding time interval is shorter than that of carbon steel, and the welding seam should be cleared with stainless steel brush. After welding, in order to better avoid local corrosion or compressive strength reduction, the surface should be milled or cleaned.

4. Precautions for stainless steel processing: In order to better avoid scratches and adhesion of air pollutants during construction, stainless steel processing was carried out under the condition of glass film. However, with the increase of time, the residual amount of adhesive liquid is consistent with the coating period of glass film. The surface should be cleaned when removing the glass film after construction, and special stainless steel tools should be used. It should be noted that high corrosivity, magnetism and stone cleaners are not allowed to contact stainless steel surfaces. If it is encountered, it should be cleaned immediately. After the completion of construction, neutral cleaner and water should be used to clean the attached concrete and dust on the surface.

Related News